개요

개요

Mid to long-term management goals

Current status of industrial accidents

| Assortment | Unit | Data of 3years | Note | ||

|---|---|---|---|---|---|

| 2022 | 2023 | 2024 | |||

| Number of industrial accident | case | 0 | 1 | 1 | - |

| Industrial accident rate | % | 0 | 0.23 | 0.26 | - |

| Lost time injury fequency rate(LTIFR) |

% | 0 | 1.32 | 1.32 | - |

| Occupational iliness frequency rate(OIFR) |

% | 0 | 0 | 0 | - |

※ Lost time injury fequency rate(LTIFR) : Number of industrial accidents resulting in injuries that occurred during a 12-month period divided by the total hours worked by all employees during the same 12-month period (number of employees * 8 hours * 5 days * 50 weeks)

※ Occupational iliness frequency(OIFR) : Number of occupational disease-related industrial injuries that occurred during a 12-month period divided by the total hours worked by all employees during the same 12-month period (number of employees * 8 hours * 5 days * 50 weeks)

Current status of industrial accidents(subcontractors)

| Assortment | Unit | Data of 2023 | Data of 2024 | Note |

|---|---|---|---|---|

| Number of subcontractors | ea | 9 | 9 | - |

| Number of industrial accident | case | 1 | 0 | - |

| Lost time injury fequency rate(LTIFR) |

% | 3.41 | 0 | - |

| Occupational iliness frequency rate(OIFR) |

% | 0 | 0 | - |

※ Limited to the number of personnel and accident cases involving partner companies stationed within the company premises.

※ Lost time injury fequency rate(LTIFR) : Number of industrial accidents resulting in injuries that occurred during a 12-month period divided by the total hours worked by all employees during the same 12-month period (number of employees * 8 hours * 5 days * 50 weeks)

※ Occupational iliness frequency(OIFR) : Number of occupational disease-related industrial injuries that occurred during a 12-month period divided by the total hours worked by all employees during the same 12-month period (number of employees * 8 hours * 5 days * 50 weeks)

Activities

| Safety and health inspection | ㆍCompany-wide risk assessment ㆍIdentification and improvement of risk factors through MYMY activities ㆍSite inspections with subcontractors ㆍRegular CEO inspections ㆍBiannual inspections of subcontractors |

|---|---|

| Training and eduction |

ㆍSpecialized training in risk assessment |

| Cooperative Safety |

ㆍOperation of committees for discussion ㆍOperation of a reporting system for subcontractors ㆍOperation of meetings between subcontractors ㆍInspection and real-time feedback through Smart Systems ㆍSupport for safety management of outsourced subcontractors |

| Improvement of safety culture |

ㆍSafety declaration ceremony ㆍAccident-free rewards ㆍListening to employees' opinions (Industrial Safety and Health Committee) |

| Health protection program | ㆍSmoking cessation program ㆍSupport for comprehensive health check-ups for employees ㆍPractical educational program for preventing musculoskeletal disorders |

| Process Safety Management | ㆍSafety inspection by external experts and PSM specialized consulting ㆍInspection of PSM implementation status, internal inspections conducted |

Activities photos

-

Firefighting training

HDC hyundai EP holds an annual firefighting competition to conduct training for emergency situations and disasters, preparing for any potential contingencies.

-

Safety declaration ceremony

To create a clean and safe working environment, employees, labor representatives, and subcontractor employees gather to share safety messages, recite slogans, and reaffirm their commitment to accident prevention in an event

-

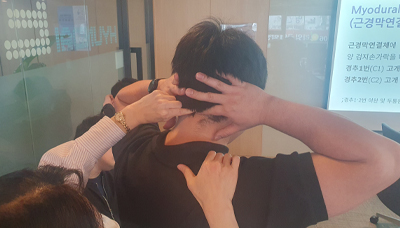

Training and eduction

Apart from regular safety training, we conduct special education sessions annually on new topics. All office and field workers have completed training on preventing musculoskeletal disorders

-

Safety management monitoring

We have developed our own safety management system to monitor real-time situations. Particularly, we have established a safety management system for employees of subcontractors to promote cooperative efforts in the safety field